Makerspace Profile

Overview

The Integrative Design, Arts and Technology (IDeATe) Network was born from Student Need, and pushed as a Campus-Wide Initiative by multiple Provosts, and the President. Located on the first (2) Floors of Hunt Library, the IDeATe@Hunt facility, acts as a supportive resource for this initiative. Hosted from a Building that is central to Campus Life, and considered a Student-Wide Resource. The facilities support a wide-range of ‘Making’- specifically focused toward Physical Computing/Embedded Computation, Media Development, and Fabrication. Focusing on these areas, creates a supportive educational resource within the Animation & Special Effects, Game Design, Intelligent Environments, Learning Media, Media Design, Physical Computing, and Sound Design Fields. From the beginning, multiple Colleges, Departments, Foundations, and Businesses have shown their support through funding and Faculty involvement. Companies such as Autodesk, Intel, Electronic Arts, and Disne; in combination with The Hillman, Benedum, and Grable Foundations are just a few significant contributors to the on-going development of the Integrative Design, Arts and Technology initiative. Large Classroom spaces, tailored with the special equipment, hardware, and resources, provide a platform for Interdisciplinary Courses that focus on specific realms of ‘Making’. In which, 30-45 Students receive education through collaborative assignments from 1-3 Faculty, all of which participating from varying departments, and disciplines. Outside of scheduled class time, these Classrooms become community spaces- providing the Student with a space to continue collaboration, research, develop, experiment, and build. A Wood/Metal Working Shop, (1) Large CNC Router, (1) CNC Mill, (3) Laser Cutters/Engravers, Multiple 3D Printing Technologies, and Large Project Build Spaces facilitate the realization of prototypes and final models. The Lending Booth, supports Hardware/Equipment Lending, where a Student may borrow Laptops, Cameras, Audio Recording Equipment, Motion Capture Hardware, and more. Some of the more commonly used Materials and Consumables are also stocked, pre-cut, and ready to purchase for Student Projects. The Facility, processes, community and culture, reflect the very nature of a Library: a space where students from all disciplines, come to work alone, or collaborate; surrounded by accessible tools and resources, that allow the continued research and development of their collective ideas. An Institution, with a Technical Background such as Carnegie Mellon’s, should be outfitted with such a Library.

Access

Any Student, who participates in an IDeATe@Hunt affiliated Course, retains access to any of the spaces, equipment, or hardware that was utilized during the Course- until they Graduate. During Fall and Spring Semesters, the bulk of our spaces, including the Media Lab, Physical Computing Lab, Experimental Fabrication Lab, Laser and 3D Printing Equipment- are available 24 x 7. The CNC Equipment, Wood/Metal Working Equipment, and Lending Booth, are available 8am-1030pm on a weekly basis. Each space, features a Card Accessible Doorway. After receiving permission to access the space, the Student simply swipes their Student ID Card to gain access to the space.

Tools, Materials and Resources

Lending:

Provides access to common equipment, hardware and materials.

1. Materials:

a. Sheet Materials include Cast/Extruded Acrylic, Medium Density Fiberboard (MDF), Medium Density Overlay (MDO), Russian Birch Plywood, Extruded Polystyrene (XPS), Expanded Polystyrene (EPS), High-Density PolyUrethane Foam, High Impact Polystyrene (HIPS), Cardboard, & Chipboard. All sheet materials provided in various thicknesses and Color.

b. Other Materials/Consumable Supplies include 3D Printing Plastics & Resins, Arduino Boards, Raspberry PI Boards, Silicones, Rubbers, Resins, Paints, and Glue.

2. Equipment:

a. Virtual Cluster includes (40) Dual Boot, Macbook Pros (Windows 8 and MacOSX), (10) Ultrabooks, (15) Lenovo Tablets, (5) Lenovo Helix Tablet PC’s, (5) Acer Tablet PC’s, (5) IPad Mini’s, (2) Samsung Tab’s) and more. All of which are outfitted with the Software required for any IDeATe Course.

b. Equipment: DSLR Cameras; Audio Recorders; Microphones; Audio/Visual Cables, Adapters, and Connectors; Keyboards; MIDI Controllers; Large Speakers; Audio Mixers; DMX Lighting Controllers; Flatscreens; Projectors; Batteries; Battery Powered Tools; Windows & XBOX Kinect Controllers; DPA Mics; Various Hand Tools; Various Measuring Tools; and more.

Standard FabLab:

Provides access to Traditional, Light Metal & Woodworking Equipment.

1. Equipment: Vertical & Horizontal Bandsaws, Drill Press, Belt/Disc Sander, Radial Arm Saw, Panel Saw, Pneumatic Tools, Battery Powered Tools, and Hand Tools.

CNC Lab:

Provides access to CNC Router and CNC Milling Equipment

1. Equipment:

a. (1) 8’x4’ CNC Router with 16” Z-Axis Motion by CNT Motion Systems Inc., capable of cutting Plastic, Wood, Foam, and Aluminum.

b. (1) Benchman Table-Top Mill, capable of milling all Non-Ferrous and Ferrous Metals.

Laser Lab:

1. Equipment: (3) 4’x3’, 80-Watt, RL-80-1290 Rabbit Laser Systems, capable of Laser Cutting all non-metals (with exception of Glass); capable of engraving anodized aluminum, and all other non-metals. Includes (3) Air Rhino Fume Extraction Systems, and dedicated Exhaust Ventilation.

3D Print Lab:

1. Equipment:

a. (6) CUBE3 Desktop Poly-Jet 3D-Printers by 3D Systems, printing in ABS and PLA Plastics.

b. (1) M2, Desktop 3D-Printer by Makergear, printing in ABS & PLA Plastics

c. (1) Creator Pro Desktop 3D Printer, by Flashforge, printing in ABS & PLA Plastics

d. (2) Form1+, Desktop SLA 3D Printers by FormLabs, printing in various types of UV Curable Resins

e. (1) Dimension 1200 FDM 3D Printer by Stratasys, printing in ABS & PLA Plastics

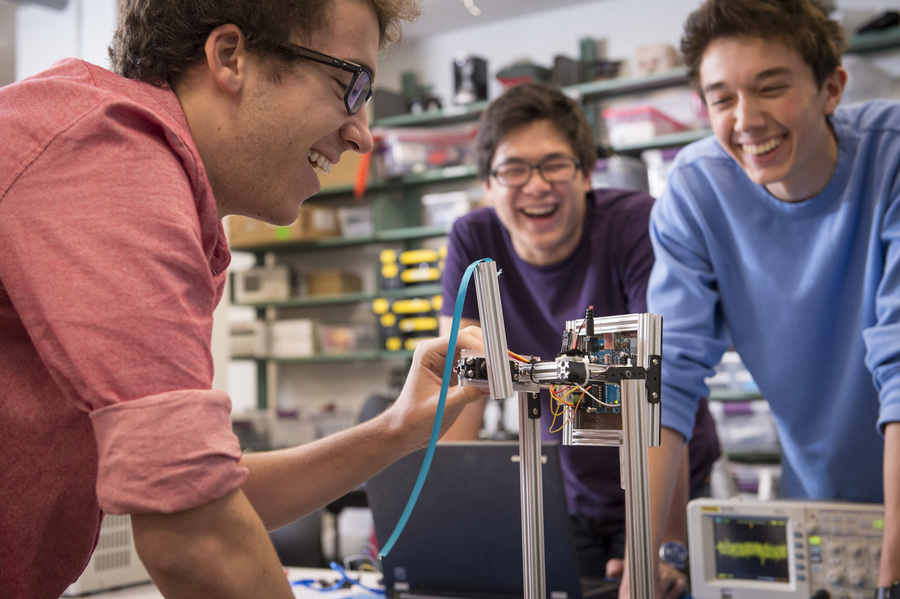

Physical Computing Lab:

1. Equipment: (5) Soldering Stations with Benchtop Fume Extraction; Thousands of small parts, electronics, circuit boards, resistors, Servo Motors, Pumps, Sensors, Acuatators, Transducers, Relays, ect.; (12) Sewing Machines, Dremel Tool, Oscilloscopes, Power Regulators, and many more.

Media Lab:

1. Multiple Audio Mixers, Large Studio Monitors, DMX Lighting Controllers, Green Screen Capabilities, Set-Design Props, Kinect Controllers, and Projectors.

2. (1) MacPro Mini

3. CNC Lighting System with (30) Lighting Fixtures

4. OptiTrack Motion Capture System w/ (8) Flex 13 Cameras

Access & Usage Costs

No Access Fees.

The students pay at-cost, for any materials used - unless Materials are covered by the Course.

Management

We have 12-15 Student Employees, who manage the Lending Desk, and record Lending Transactions, Returns, and Material Purchases. A full-time Facilities Manager, coordinates their Hiring, Training, Tasks and Schedules; while attending to on-site Equipment/Facility Issues and Inventory. A full time Director, coordinates the continued development of the spaces, equipment, procedural elements, and collaboration between Faculty and Students. Two Full-Time Staff coordinate fiscal budgeting, Events, Community Outreach, Advising, and the development of the Undergraduate + Graduate Level Curriculum. A full-time Dean, with the assistance of a full-time Associate Dean, coordinates collaboration between Higher Level Administration, including the President, Provosts, Deans, Department Heads, and Faculty. In addition, they work alongside the Full-Time Staff, providing oversight, and assistance with the development and implementation of solutions.

Training

IDeATe provides a platform in which the Student Community can achieve specific skill-sets through (2) Methods. Taking a course will provide specific skills in certain areas. Full-Semester, Half-Semester (Mini’s), or Short-Form (Micro’s) Length Offerings allow the Community to ‘pick-and-choose’ how they would like to learn. Full Semester Courses cover a lot of information, and require heavy collaboration. Mini Courses primarily focus on delivering Content quickly, and collaboration is limited. Micro Courses deliver a lot of content in 3-4 Days, during which, collaboration is natural. Some students may have experience, some may not- regardless of experience level, the Students team-up, to complete their required projects (two heads are better than one).

The other method in which training, or development is supported, is through community. Our culture encourages this type of learning. Students who want to learn something, may barter or trade information with each other. For instance, a student wants to learn Arduino, while another wants to learn 3D printing. They choose to work with each other, and teach/learn from each of their experiences.

Use and Activity

IDeATe features multiple spaces, that categorically fall into these groupings:

Studio A & B: Multi-Purpose, Community and Classroom Space. These spaces are used as Classrooms for less-intensive ‘Maker-Courses’. They are more traditional learning environments, as they are outfitted with large screens for presentation, several desks, chairs and Dry-Erase Boards. In addition to supporting courses, these spaces may be used for Lectures, Workshops, or Meetings. Outside of Class-time, these spaces morph into a University-Wide work-zone. Students may be studying Calculus, while others are collaborating on Web Design.

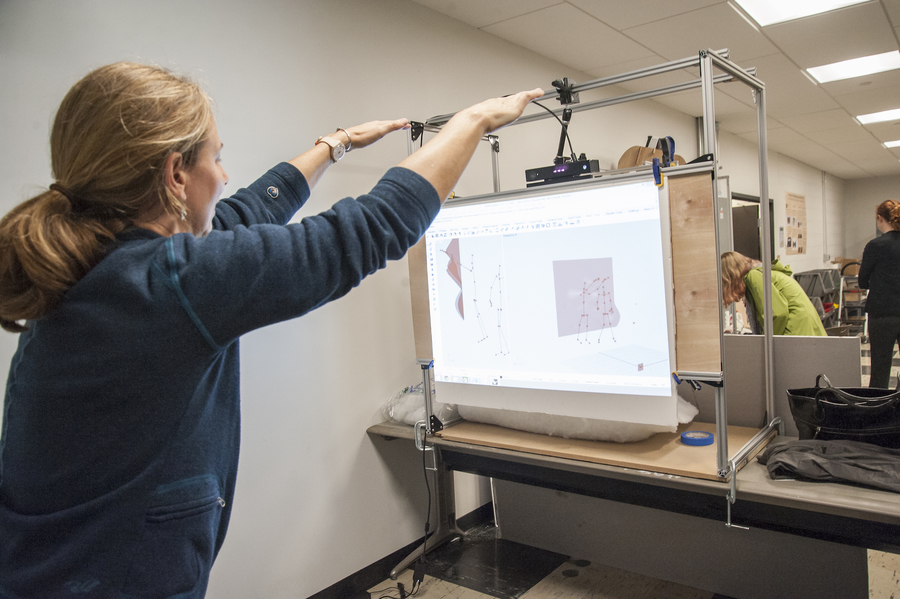

Physical Computing Lab, Media Lab, and Experimental Fabrication Lab: Multi-Purpose, Community, Classroom, and Project Space. Each of these spaces, are tailored to support Learning, Instruction, or Experimentation for specific workflows. As a result, each space is tailored to support Faculty, Staff, and Student experiences- by providing some of the more common Tools, Hardware, Equipment, and Materials related to each spaces supported processes. During Class-time, the space is typically dedicated to the Students and Faculty providing the course. Outside of class, the IDeATe Community may use the space to prototype or experiment. The Physical Computing Lab offers a Clean Room, for small projects of instruction involving embedded computation. The Media Lab provides a large, sound-proofed, dark-room space for experimentation or instruction involving Sound Design, Set Design, Video Game Design, Motion Capture, or Lighting Design. The Experimental Fabrication Lab provides a Large Classroom space, for instruction on Digital Fabrication workflows such as 3D Printing, Laser Cutting, or CNC Routing. Additionally, this space provides areas for large-project builds, and immediate access to the Laser and 3D Printing Equipment. Although each of these spaces may be used for Lectures, Workshops or Meetings; if the event prevents access, it must be approved by our Community before approval is granted.

CNC Lab, Standard Fab Lab, Laser Lab, and 3D Print Lab are single function, Machine Spaces. Essentially, the space becomes a resource- as it is tailored to suit the specific equipment process occurring within the space.

Culture and Community

The change, is visible at multiple levels. From a Student perspective, they have limited resources within their departments. When they want to ‘Make’ something, they are forced to browse, beg, and cheat their way into one of the many inaccessible maker facilities, we have on campus. These facilities are inaccessible, because each Department, limits access to their students only. (Rightfully so, as they (the department) are the primary source of funding for such a space) This means, that Student ‘A’, from Department ‘X’, may have extensive experience on using Laser Cutters; but when he/she asks for access to a Laser Cutter in Department ‘Z’, they are turned away. To create, maintain, and provide a space that ANY Student can use, is extremely beneficial for multiple Departments, Groups, and most importantly the Student. The Student, who is accustomed to each department working on their own, begins to see the benefits, and positive outcomes of shared access. It also provides a new method of learning: “Learning-by-Seeing”. Architecture Students are familiar with how to turn 2D Cutting Geometry into a 3-Dimensional Object, by using a Laser Cutter. Computer Science Students are less familiar with this process, but are great at making objects slot/fit together. By having a shared space, these two groups collide more frequently, and see how they might do something differently to achieve their goals. This exposure, to the different ‘techniques’ one might use, is something that a Student can only learn by seeing, or browsing the internet. This common interest in making, brings multiple groups together, to learn from each other. More notably, this common interest acts as an ‘ice-breaker’; and these groups meet, talk, interact and learn from their shared experiences.

At a Departmental Level, the Student Projects serve as a wonderful example of what happens when Communities come together. Department Administrators begin to participate more frequently, when they see the Community & Culture that develops from a shared space.

Challenges and Lessons Learned

1. Spatial Access Management: How do we provide a universally accessible space, as often as possible?

a. We are located in a Library, which is open almost 24 x 7. This allows us to keep our spaces open as frequently as possible. We limit access to specific spaces that require training, by implementing a Student ID Card-Swipe Lock. Once approved, they have access to the space/equipment for as long as they attend the University.

2. Equipment Access: How do we provide access to Equipment, as often as possible, without increasing hazard?

a. We collaborate externally and internally with Universities, Makerspaces, and Museums; to determine best-practices. Some of these collaborative discussions, have expanded our abilities. For instance, Environmental Health and Safety, provides Fire-Safety Training, available to ALL Students across the campus. This training, is required for any Student planning to use the Laser Equipment. IF the student participates in the Training, they are allowed to use the Laser Equipment, unmanaged and alone- during any time of the day!

b. You should also determine if the equipment is life threatening. This will determine whether or not the Equipment should be accessible when someone is alone.

c. Implement a Lending System. Some items, can be kept in a central location. Members from your community can borrow these items on an as needed basis. (e.g. Cameras, Audio Recorders, Projectors etc.)

3. Staffing: How do we manage Equipment, Spaces, and Materials?

a. Keeping a list of Students in your community, and knowing who has extensive experience is key. Hiring these Students as Employees, will provide knowledgeable Staffing.

b. More notably, the Student should work well with others, and care about the space. This helps, as they will provide troubleshooting assistance frequently, and provide input on how the space is being used (to Administrative Staff). (e.g. We are out of ‘x’ material, we need to get rid of this ‘table’ etc.)

c. Keeping Student Staff is essential. When a Student needs help, they are more likely to be comfortable with Student Staff assistance, than Administrative Staff.

d. Make your Student Staff “stand-out”. Give them T-Shirts, Bandanas, or Uniforms! This will help the Student User, in finding help- but, it also makes the Student Staff feel more prominent.

4. Community & Culture: How do we inhibit culture, and maintain Student Ownership of the space?

a. Have shows! Support your Student Community, by inviting the entire campus community to come see your space, and see what Students in Facility-related Courses have made.

b. Display your student work! Designate specific locations around the campus to show off student projects.

c. Encourage Student Led Workshops- provide them with the space and tools to educate others.

d. Include Students in your decision making- create a d-list of all students in your community, and ask them for their feedback. Implement action, and change, asap! They want to see their input was worthwhile!

e. Support Student Community Projects: Do you want RFID Control installed on all heavy equipment? Do you want Digital Signage outside of each of your rooms? Assign these projects to members of your community, provide the funding for prototypes. See to it that Student Projects become a part of your facility.

f. Get out of the way: STOP preventing them from doing their work, and do everything you can to support it. Sometimes, this requires that you get out of the way. Your responsibility, is to make sure they are safe (and that it is legal) while they do it.

5. Training: How do we provide Training to Students, Faculty, Staff, and Alumni- whether they are experienced or not?

a. Some users are Experienced, and just want access. Some users have no Experience, but need quick training.

i. Provide Micro Courses: ~16 hrs of training, spread out over 3-4 Days.

ii. Provide Workshops: Length, and Instruction vary.

b. Some users want to meet other people, and their experience on equipment is irrelevant. They find value in the classroom experience.

i. Provide full semester Courses.

c. Some users want the best of both worlds: quick education, quick experience, limited classroom experience

i. Provide Mini Courses/Half Semester Courses. Focus on content.

Advice to other Makerspaces

Focus on development of Space first, Equipment comes last. If you want a Makerspace, that supports Collaboration and Making, you must begin by COLLABORATING! Ask for help, ask for reference, ask for input. Find out who is doing it right, and learn about what to avoid. Talk to these groups, and learn from their experiences! Take a Professional Development Course on Makerspaces. Lastly (but not least), the Student, is your first priority. Keep them informed, and ask for their input. They will tell you what they want! This inclusion, will be the start of your Community, and in my opinion, Culture & Community MAKE a makerspace- not the space, not the equipment.