Makerspace Profile

Overview

The UH FabLab is located on the 4th floor of Holmes Hall. The space was originally a physical electronics lab. During the 2011 Solar Decathlon, the space was appropriated to develop home automation devices, renewable energy sensor modules, and interactive lighting systems. Since then, many Making tools centered on design and fabrication have been either donated or purchased to expedite device prototyping. Operated by passionate faculty, graduate, and undergraduate students, the space has become a collaborative workspace encouraging free thought and innovation. Projects include collaborations from the Department of Electrical Engineering, Mechanical Engineering, and Civil Engineering as well as the College of Tropical Agriculture and Human Resources (CTAHR), School of Ocean and Earth Science and Technology (SOEST), the Institute for Astronomy (IfA), John A. Burns School of Medicine (JABSOM), and the School of Architecture (SoA). It has been supported in part by the Renewable Energy and Island Sustainability (REIS) project, the Department of Navy, the Hawaii Space Flight Lab (HSFL), the Native Hawaiian Science and Engineering Mentorship Program (NHSEMP), local donations, and internal College of Engineering funds.

Access

Access to the FabLab is currently restricted to a handful of graduate students that offer guidance and mentorship to undergraduates, graduates, and professors that seek to learn rapid prototyping principles and techniques. So long as a supervising faculty, staff, or grad student is present in the lab with the door unlocked, anyone with proper safety training is welcome to use the facilities. For using more advanced machines, students operate on an apprentice system where more senior students train more junior students.

Tools, Materials and Resources

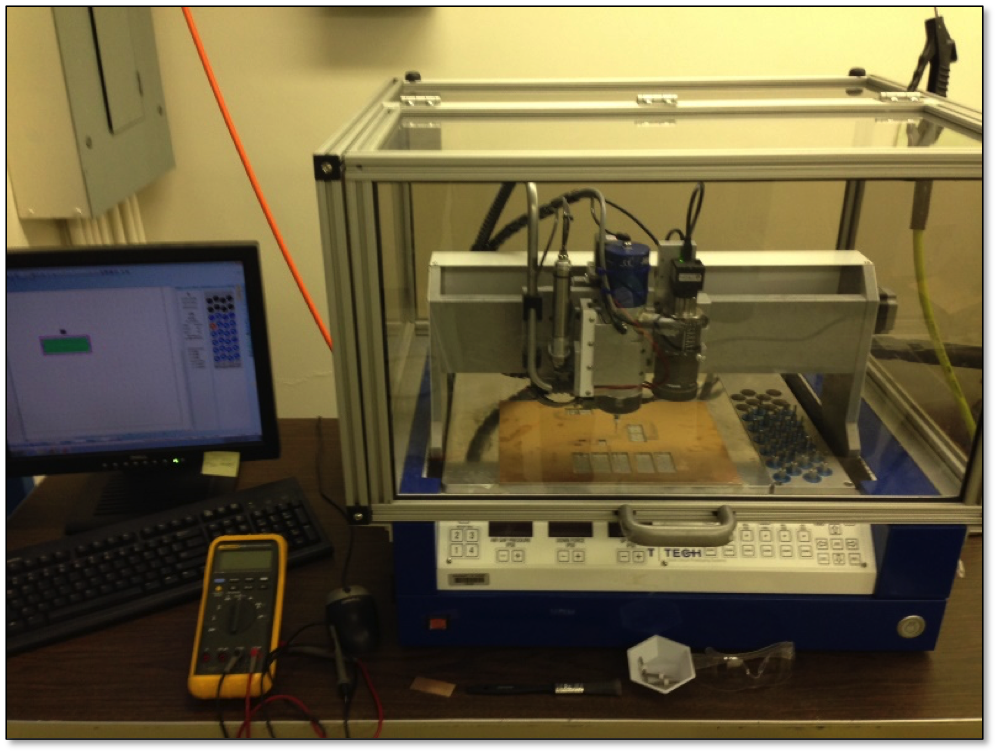

Dual extrusion 3D printer, PCB milling machine with an automated 24 tool pod, reflow oven, photolithography for soldermasking/silkscreening, laser cutter/engraver, electroplating, soldering tools, and diagnostic and characterization instruments. Materials include various plastics (PLA, ABS), plastic and wood sheets for the laser cutting, and a number of chemical choices for plating and experimentation. Additional equipment acquisition is planned for the near future which will include pick-and-place tools, CNC equipment, and additional 3D printers and laser cutters.

Access & Usage Costs

Students are expected to supply their own components for circuit boards, although the copper board materials are free for small projects. Students are also expected to supply their own plastic reels for 3D printers. All other tools and materials are free for students.

Management

Faculty and staff help manage the FabLab. Currently the FabLab is mentored by dedicated graduate students who also conduct research within the space. Other students and professors may contact the leading faculty or graduate students directly in order to access the lab and receive guidance for using the facilities.

Training

Training is provided on an as-needed basis for undergraduates, graduate students, and professors. Students working on design projects make appointments for private training sessions, while electronics classes are trained in groups for laboratory experiments. A number of how-to videos have been posted on YouTube for aiding with educating students on equipment usage.

Use and Activity

Many undergraduate design projects take place within the lab. The lab overseer provides training in PCB design, programming, and fabrication. Some undergraduate courses tour the lab and take advantage of the facilities as part of the coursework. The space is also used to develop products for research grants.

Culture and Community

The ease of access and availability of an expert remove barriers for undergraduates when it comes to realizing innovation. A number of student-led projects that have used the FabLab have gone on to place in the UH Breakthrough Challenge and the UH Business Plan Competition. This success has fostered continued growth in capstone design projects that make use of the fablab tools for producing functional prototypes.

Challenges and Lessons Learned

Restricted access and lack of training for the majority has resulted in an overwhelmingly large amount of pressure on the lab overseer. Having to come in on weekends to ensure the completion of other students’ and professors’ projects is often an underappreciated responsibility. The lab is shifting to a more accessible form, allowing properly trained students to come and go as they please.

Advice to other Makerspaces

Be prepared for things to go wrong, and for equipment and materials to break. Having a proper training program is essential to maintain the space operability. This may mean having an on-site technician to prevent disaster.