Makerspace Profile

Overview

The Design Studio consists of 5,500 square feet of rooms on the first floor of Spencer Lab. The rooms offer various materials and project resources, including computers, 3D printers, sewing machines, and lumber. The Design Studio layout is across several rooms, with such names as “The Pit”, “The Fab Lab”, and “The Hack-A-Torium”.

Access

Mechanical engineering students have access to the space 24/7, and it is open to the UD community during normal business hours.

Tools, Materials and Resources

Two 3D printers, a full metal machine shop, woodworking room with chop saw, drill presses, hand tools, electronic prototyping equipment, microcontrollers, surround sound speakers, projectors, rolling white boards,

Access & Usage Costs

The space is free to use for students and the UD community. Modest fees are charged for consumables such as 3D printing material if usage exceeds a certain threshold. Supplies are restocked through the Department of Mechanical Engineering and other donors.

Management

We have about 10 undergraduate students as teaching assistants assigned to the space that help maintain it and implement upgrades. There is also a design studio committee of faculty members within the department.

Training

Safety training is required of all students before using the shop tools, and an Integrated Design course runs in the space. Additionally, a one credit course called MakerSeries runs each semester and covers all different types of making techniques from soldering to sewing.

Use and Activity

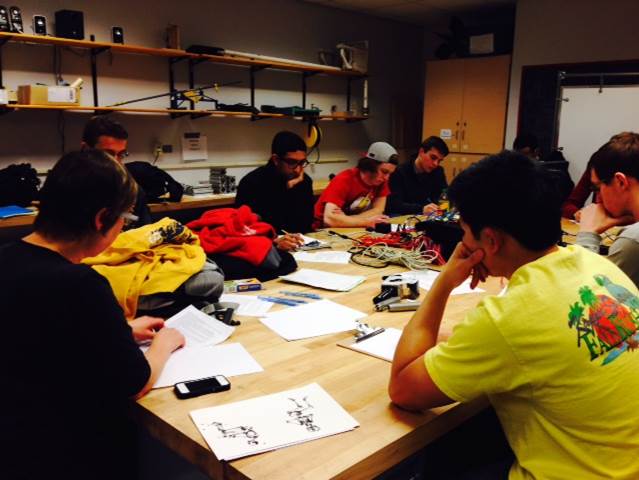

The space is heavily used every day and night by students, mostly mechanical engineers. The MakerSeries course runs in the space, as does Integrated Design, and most teaching assistants in the department hold office hours in the spaces.

Culture and Community

The Design Studio makes it very easy to go from idea to prototype very quickly. Students are constantly helping each other out and learning from each other since the flow of students and ideas is fluid through all the rooms of the studio.

Challenges and Lessons Learned

Not all the rooms have 24/7 access due to key card issues that we are trying to resolve through fundraising for the space. We are also continuously fundraising to replace supplies and upgrade the machines.

Advice to other Makerspaces

Just do it! Do it on whatever budget you have, then expand as you grow.