Goals of the project

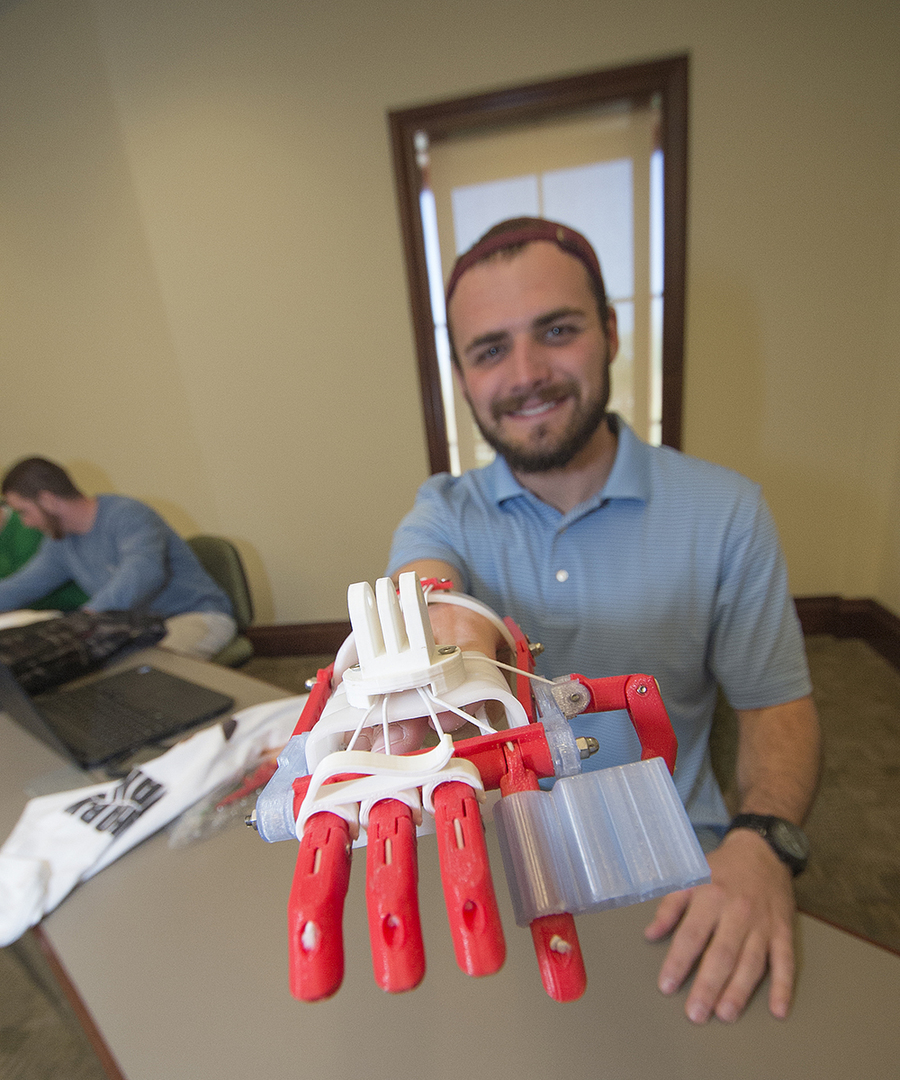

This project took advantage of three convergent trends: the emergence of low-cost 3D design software and fabrication, the increasing adoption of the “lean startup” approach in modeling new ventures, and the economic cost of healthcare in the U.S. is development of alternative, affordable services and products to provide access for both served and un-served patient populations. The cost of sophisticated, electronic prosthetics is extremely costly for non-veterans with medical insurance and prohibitively expensive for those without medical insurance and those in developing countries. During Spring 2015, the Department of Management and Department of Physical Therapy coordinated with RobohandUSA, a non-profit, open-source organization, and with the company, Virginia Prosthetics of Roanoke VA, to redesign and test demand for low-cost 3D-printed hand and lower arm prosthetics. Doctor of Occupational Therapy students acted as consultants for undergraduate business student teams in the design, development, and testing of these 3D-printed prosthetics. These interdisciplinary student teams completed the project by entering into a design and business model contest sponsored and judged by Virginia Prosthetics and other business and community leaders to evaluate the perceived value and economic feasibility of the 3D-printed prosthetics.

Nature of the Collaboration

First, we developed bridging between disciplines on campus and with communities of practice in the regional economy. Delivery of health care devices and services in affordable, innovative ways requires cross-disciplinary and multi-stakeholder participation and coordination. Enhancing students’ awareness and engagement in such complex problem-solving is excellent preparation for the school-to-work transition. Secondly, this project advanced peer-to-peer education in preparation for problem-centered, applied learning in a time constrained, professional environment. This project promoted “learning-by-making” through the application of new 3D design and fabrication technology fostering creative and innovative thinking about patient needs. Sometimes referred to as “blended reality,” this approach mixes digital and physical technology. Lastly, a complementary high-impact practice to this problem-centered approach was the “gamification” of outcome rewards for students during a simulated “Shark Tank” investor pitch contest.

Skills

Design, prototyping, 3D printing, manufacturing, patient care, customer research, business model development.

Tools

CAD design software, 3D printers, assembly and finishing hand tools.

Process

The original idea was developed through interactive consultation between the faculty participants, the RU High Impact Practices Office, the RobohandUSA Director, and technical staff at Virginia Prosthetics. It was then integrated into two parallel courses during the

Spring semester with team formation, doctoral student consulting role development, and prototyping and business model milestones for iterative development. Final activity was participation in a mock investor pitch contest of both the prosthetic prototype and business model.

Milestones

There were three interim showcase milestones for 3D prototype development (design, 1st prototype, 2nd prototype) and one final presentation (final prototype) with interim customer research activities associated with successive development. Interspersed with the prototype development milestones were three business model development milestones involving presentations and timed to converge with the presentation of the final prototype features.

Challenges encountered

Business students and doctoral students were in different disciplines and in different geographic locations so electronic communication was very important. The PT doctoral students provided disciplinary expertise to the business students in functional design of a medical device and patient needs. Likewise, the business students provided the PT students an awareness and understanding of what it takes to create an economically self-sustaining business in an ever changing healthcare market. This cross-disciplinary peer-to-peer learning is challenging, yet rewarding. Both student groups developed an appreciation of benefits of similar projects they would often encounter post-graduation in companies and organizations they join. Frequent, regular communication was required to avoid misunderstanding and to allow for development of a common perspective.

Major outcomes

The project provided the students insights into the potential for low-cost medical device alternatives to enhance affordable healthcare benefits which could exist without healthcare coverage. They also found during the process that redefining problems and solutions often leads to productive insights and applications. For example, the prototyped products extended thinking of patients as needing to fill a gap in physical performance and began to think of how these devices could actually be tailored to providing emotional and psychological benefits (e.g., enabling former musicians to play again).

Innovations, impact and successes

12 different types of upper limb devices were developed, but the definition of what populations could benefit and how they could benefit extended beyond the existing medical device framework to consumer products which could have beneficial implications for entertainment (e.g., children’s toys) and age-constrained physical limitations (e.g., new type of gardening tools).

ijclellan

ijclellan

Julia Castleberry

Julia Castleberry

Ty Esham

Ty Esham

.thumb.jpg?1452790921)