Goals of the project

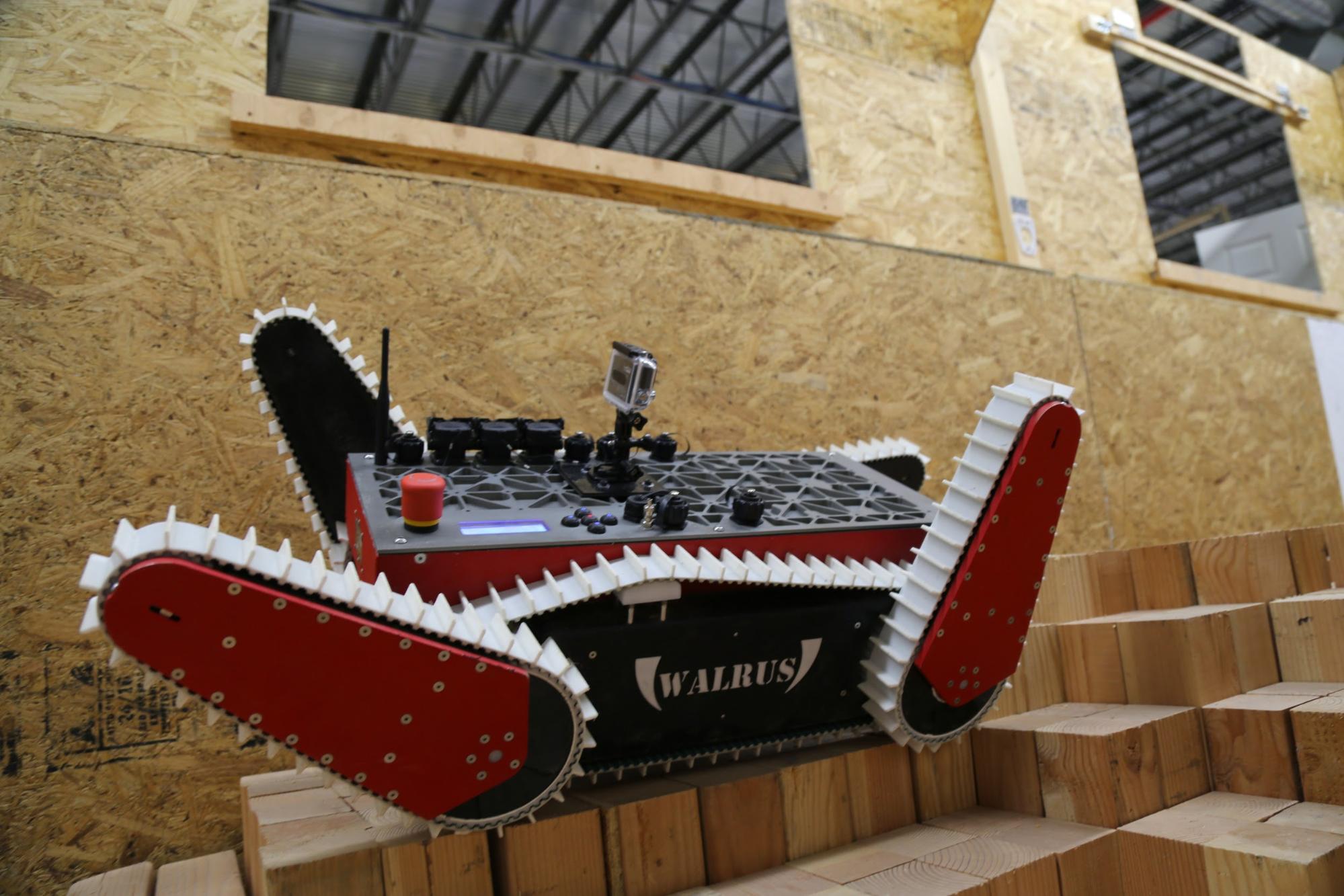

Search and discovery rovers have evolved to play an essential part in disaster relief efforts and humanitarian aide. With features such as supervised autonomy, high-definition vision systems, and increased mobility, this project aimed to create an amphibious rover to aid in the search and discovery of persons during disasters. Such a rover would not only give relief teams more information about the situation at hand, but also eliminates the danger of sending search parties into harsh and high-risk environments. The addition of water mobility allows teams to deploy the Water and Land Remote Unmanned Search (WALRUS) Rover after disasters such as tsunamis or hurricanes. A rover with amphibious capabilities exceeds the maneuverability of current commercial platforms, and enables a wider range of mission profiles.

Nature of the Collaboration

As part of any robotics engineering project, the WALRUS rover required careful collaboration between team members to combine skills in computer science, electrical engineering, and mechanical engineering to ensure success. The rover is a complication electromechanical system and decisions in one subsystem in many cases had consequences for other subsystems. Through close collaboration, the team managed the integration of the subsystems to ensure that the rover met the design and engineering requirements outlined at the beginning of the project.

Skills

Manufacturing: The entirety of the rover was manufactured using on-campus resources requiring skills in the operation of tools ranging from hand-operated ones through the large CNC machines on campus.

Design: The rover was designed and prototyped over a period of 3 months requiring proficiency in CAD/CAM, thermal analysis, stress analysis, materials selection, manufacturing processes for the mechanical aspects, software architectures, use cases, and design paradigms for the software aspects, and PCB layout and simulation, power budgets, and electrical safeties for the electrical aspects.

Coding: The software to operate the rover is implemented on the open-source ROS platform running on top of Ubuntu 14.04. Strong coding skills in C++ and Python with a detailed knowledge of the operation of ROS was required to ensure the robot’s operation. In addition, low-level firmware written in C for the embedded controllers bridges the operation of the hardware systems to the main computer.

Algorithms: A custom designed stair-detection algorithm helps the robot detect and center itself on staircases. This satisfies the requirement for “supervised autonomy”, reducing the cognitive workload on the human operator.

Human-Centered: Ultimately this rover is to be used by human operators, requiring testing and analysis to understand what the best way to interact with the robot is. Interviews with existing robot users and designers enlightened the team on how people would be expected to interact with the robot. This directly influenced the user interfaces and implementation of the “supervised autonomy” features.

Tools

Software Tools: C,C++, Python, GCC, OpenCV, PCL, ROS, Linux, Github

The rover uses many open source libraries and algorithms to implement its high-level functionality. The custom functionality is implemented in a variety of languages. Github keeps all the code safe and available for easy collaboration.

Mechanical Tools: Solidworks, Solidworks PDM, MasterCAM, Manual (Drill Press, Band Saw, Lathe, Mill) and CNC (Haas Mill and Lathe) machines, Makerbot 3D printer, Stratasys 3D printer, Laser Cutter

Each part on the rover is conducive to different manufacturing techniques. After design in Solidworks, the appropriate manufacturing technique is used to make each part to the specification.

Electrical Tools: Altium PCB Designer, DFM Check, Soldering Iron, Hot-rework Tool

The electrical components are designed and simulated in Altium. They are then assembled and integrated using standard tools such as soldering irons.

Process

The project started as an idea for an amphibious search and discovery rover in August 2014. The project was roughly split in quarters corresponding to WPI’s undergraduate terms. During A term (Aug-Oct), the team interviewed stakeholder and developed relevant design requirements. Several small scale prototypes were created at this point. During B term (Nov-Dec), the major design work on the rover was completed. During C term(Jan-Mar), the manufacturing and integration phases were underway. Finally during D term (Apr-May), testing and debugging was carried out.

Milestones

Two prototypes created in A term preceded to the final version. The first was a ⅔ scale model to decide the size format and shape of the rover that would enable it traverse stairs and rough terrain. The second model was a plastic mock-up used to conduct drag tests in WPI’s rowing tank to characterize the robot's motion through the water.

At the end of A-term, the team held a preliminary design review to solicit feedback from the engineering faculty and students. At the end of B-term, another design review was held to address manufacturability and integration details. Finally, in late April the final rover was unveiled and presented at WPI’s Project Presentation Day.

Challenges encountered

As in any robotics project, there were many challenges. The rover went through several design iterations to balance the tradeoffs made in different subsystems. There were many challenges ensuring the rover meets its design specifications, especially with its ability to float in water and manage its power to meet its operational power requirements. The process taught the team that success only comes from close collaboration and holistic approach to the problem combining the various different skill sets of different team members. The key insight is that prototyping and simulation are critical to the success of the project. The earlier problems and issues are caught and address, the easier and cheaper the process is. This is only possible with a team built on trust, collaboration, and hard work.

Major outcomes

In April 2015, we had a completed amphibious rover prototype. On May 1st, 2015, the team competed in the Intel Cornell Cup held at Kennedy Space Center in Florida and won Grand Prize, beating 20 other teams. On May 18-19, the team brought the rover to the Austin Fire Department for testing and integration with the Robotic Emergency Deployment (RED) team. Finally, the robot will be showcased by the Smart Emergency Response (SERS) team at the NIST Global Cities Technology Challenge.

Innovations, impact and successes

The major innovation is that the team built an amphibious search and discovery rover capable of also traversing rough terrain and stairs. There are commercially available products that can do land traversal or water traversal well, but few combine the two in a package such as WALRUS. We hope that the concepts learned and demonstrated on the WALRUS rover will encourage more innovations to enable the next-generation of disaster response robotics.

Taskin Padir

Taskin Padir

Sonia Chernova

Sonia Chernova

stafford

stafford

Mitchell Wills

Mitchell Wills

Brian Eccles

Brian Eccles

Tim Murcko

Tim Murcko

Brendan McLeod

Brendan McLeod

TJ Watson

TJ Watson