Goals of the project

Each year for the past five years, sophomore engineering students at James Madison University work to design and build human-powered vehicles for a community member with needs very different from their own as a result of cerebral palsy. This year-long, client-based, design project design project is interwoven with instruction in a two-course design sequence generally taken during the student’s second year within the Madison Engineering Department.

From year to year, while the theme of the project remains the same, the designs have varied greatly as each client’s needs and requirements have been different. The overarching goal is to expose the students to an experience that transcends the classroom, and in the process, not only teach the students design but also that they are part of a larger complex system where their decisions and actions as an engineer can (and likely will) influence others.

Nature of the Collaboration

This project has been successful because of ongoing collaborations.

(1) Each year, through the efforts of Dr. Moran, a new client is identified for the project. The client agrees to be available a couple days through the week to interact with the students, and to maximize the client’s time, the student is enrolled in Dr. Moran’s Overcoming Barriers program, a physical activity mentoring program for individuals with disabilities. Through Overcoming Barriers, the client works with Dr. Moran and his Kinesiology/physical education students at JMU to develop an individualized workout program that develops the client’s motor skills and health-related physical fitness in preparation for delivery of the human-powered vehicle. Through Overcoming Barriers, a relationship is built each year between the client, the kinesiology student mentor who works one-on-one with the client, the client’s parents, and the engineering students. The kinesiology student mentor is the link between the client’s improvements in their physical fitness program and the engineering students understanding of those needs, abilities, or improvements.

(2) A local bike mechanic/builder helps the students learn about bicycle subsystems and functionality as well as how to use the tools in the department-provided bike tool box. Additionally, the local bike mechanic/builder holds office hours in the studio from conceptual design through beta prototype to help the students refine, detail, and construct their ideas. Students learn to trust and rely on this partnership as a valuable resource through the academic year.

(3) Similar to the partnership with the local bike mechanic/builder, students work with the University machinist and the engineering lab manager to construct their designs. Through these partnerships, students complete the tool and safety training necessary to work with engineering fabrication and machining equipment. Students take engineering drawings and raw materials to the University machinist to have parts fabricated. The engineering lab manager is a certified welder and performs all project welding.

Skills

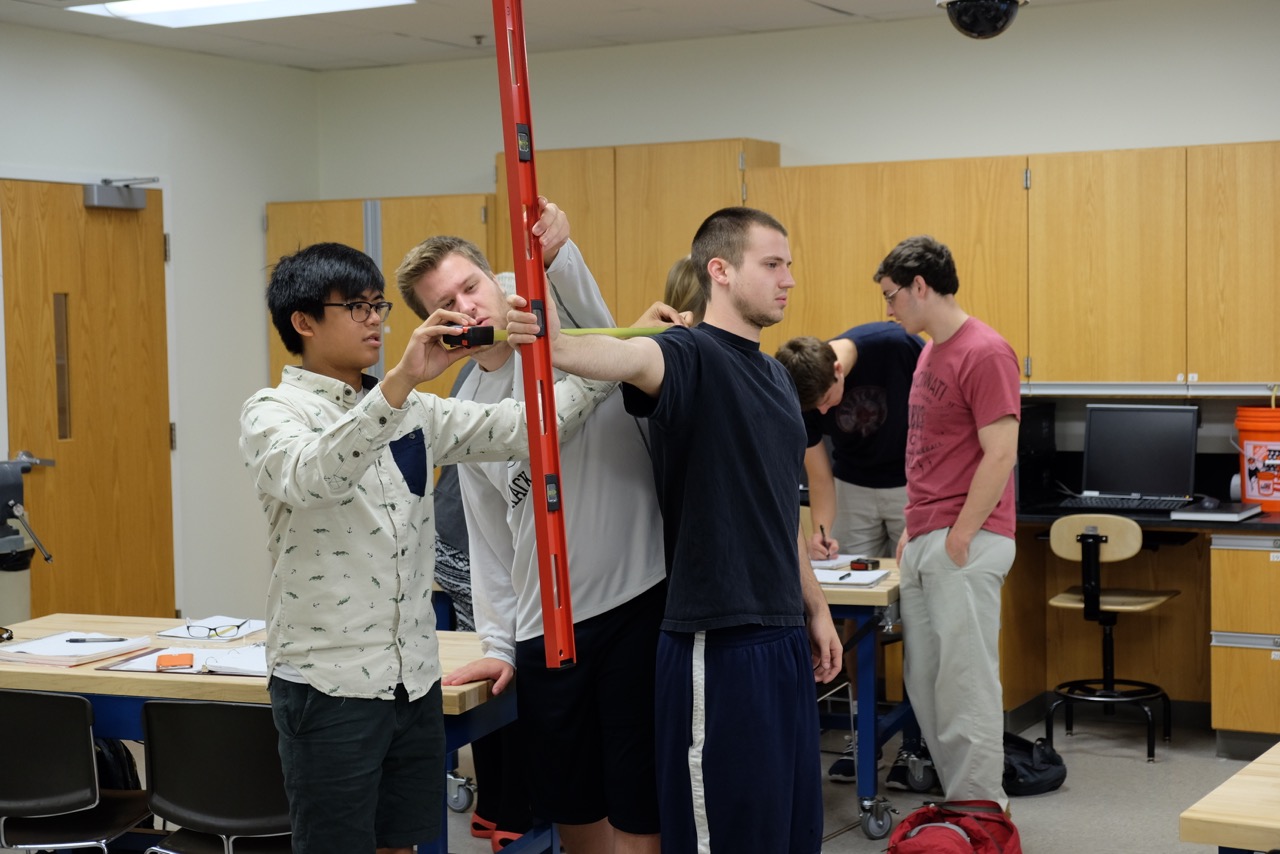

Students construct actual functioning human powered vehicles. In order to be prepared for this opportunity, students must complete a variety of tool trainings.

(1) Basic tool training in the engineering program occurs for all students during their first year. This includes learning to use a band saw, a drill press, and a variety of powered hand tools.

(2) Following basic tools training, students complete mill and lathe training; this experience does not allow students access to the mill and lathe, but it does provide them with the knowledge of the each tools most basic capabilities.

(3) During sophomore design, student teams are trained to tear down and rebuild a bicycle. This training allows students access to mechanics tools boxes and bike tools.

(4) While completing the human-powered vehicle project, students are exposed to SolidWorks, and occasionally students find their way into Madison Engineering’s student-staffed prototyping lab to make 3D prototypes of their CAD models.

Tools

Lathe, Mill, Band Saw, CNC, Welders, Grinder, Drill Press, Reciprocating Saw, Mill, 3D Printers, Sewing Machine, Bike Tools, Mechanics Tools

Process

Students in the first semester are transitioned through the design process phases of understanding the problem and conceptual design. Students are taught that design is a journey of asking the “right questions” and then seeking out appropriate answers. The journey starts with the students gaining an understanding of themselves, the people that make-up their team, and developing an appreciation of their surroundings. Students are asked to explore their values with respect to team work and engineering before transitioning into assignments that require students to deconstruct actual engineering ethics cases using the NSPE Code of Ethics to understand the potential ethical implications associated with engineering practice. Students compare their responses to the actual NSPE rulings and reflect on the differences.

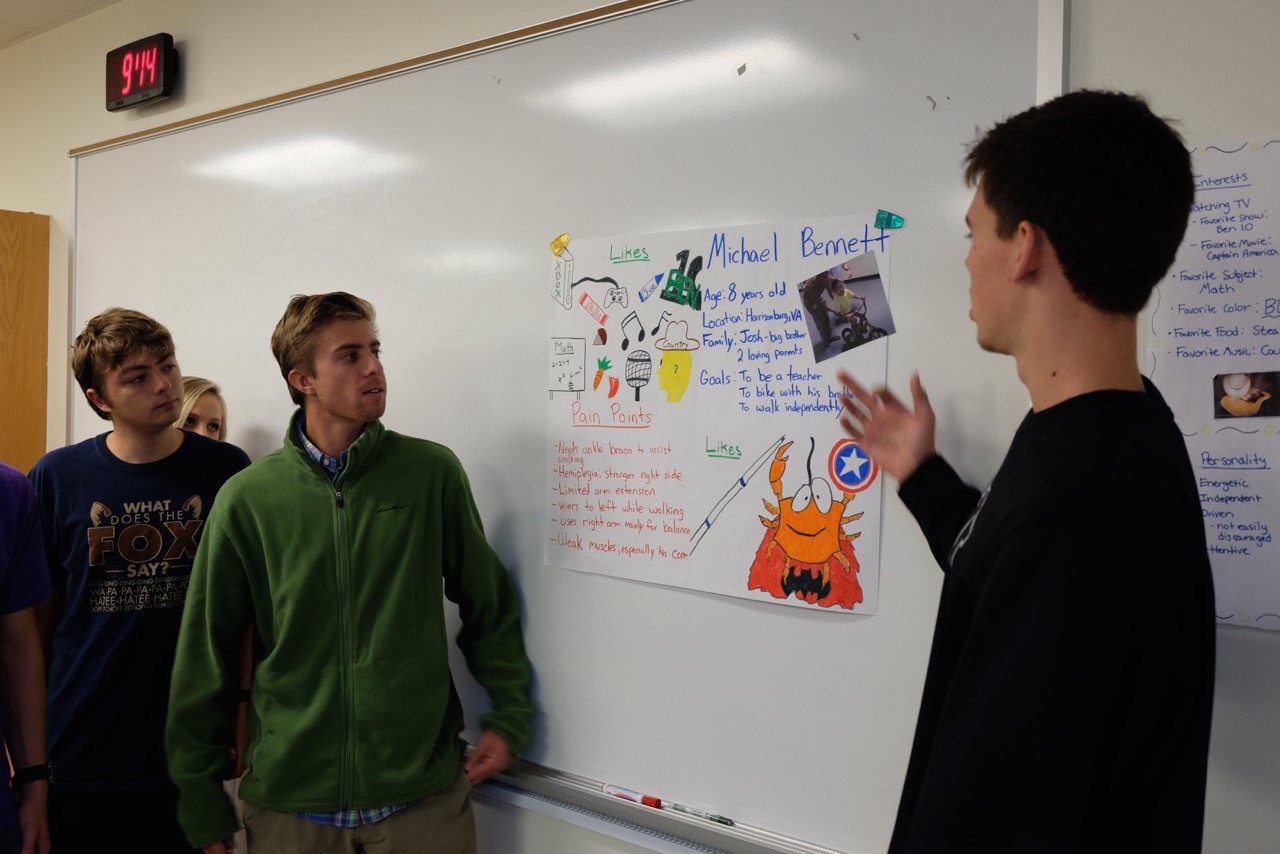

About a month into the class, students are first introduced to the client through video and a guest lecture given by a kinesiology professor Dr. Tom Moran. Students learn about cerebral palsy, what it means to live with a physical disability, and how it affects a person (the professor and the client) on a daily and long term basis. To reinforce the activity, the students are guided through research assignments, and an empathy exercise is used to help the students understand the challenges faced by the client. Students use the persona method to develop personas of the client that are displayed on the walls of the studio for both semesters to act as a reminder of the client.

Students’ overarching task through the first semester is to generate numerous conceptual designs that may be viable options to meet the specific client needs. As a team of four to five students, students apply the tools taught for individual and team-based, in-class exercises in order to produce designs that are formally presented to the client and the client’s family at the conclusion of the first semester. Students receive feedback (often as outbursts during their presentations) such as, “Who thinks this stuff up anyway?” and “That’s Impossible!” which continues to reinforce that the students are designing for a client’s needs, not their own.

On the first day of the second semester, students are placed in a new team of eight students and are asked to revisit all of the work performed during the prior semester (i.e. revisit the client, evaluate all decisions, iterate design concepts, and arrive at a new conceptual design). A second empathy exercise occurring during this iteration of the prior semester’s work reinforces that the needs of the client are very different from their own.

To understand the feasibility of their ideas, students model components of their designs using drafting software and create proof-of-concept prototypes to test sub-system feasibility. Using these models, student gather more feedback from the client before being introduced to the concepts of material selection, calculation of overall mass center of mass, the calculation of the force in each member of their design when statically loaded. Through this physical and analytical modeling, students begin to understand the limitations of “real” designs; in other words, students begin to transition from conceptual design to detailed design.

To help students through the process of constructing alpha and beta prototypes, consultation periods are held between student teams and course instructors. These consultation periods provide an opportunity for open dialog to discuss progress and roadblocks. Additionally, students work with a local bike mechanics expert for guidance while building their alpha and beta design prototypes. The Human-Powered Vehicle project culminates with the students demonstrating their final product (a beta prototype) to the client, his or her family as well as the University and the local community. One student is hired over the summer to transition the beta into a final design that can be provided to the client in exchange for their time participating in the Human-Powered Vehicle project.

Milestones

Each year, the project runs according to the following timeline:

- Fall Semester (First Day) – Teams assigned.

- Fall Semester (End of October) – Design Objectives, Functions, Specifications Identified by student teams.

- Fall Semester (Start of December) – Conceptual design finalized by student teams and presented to stakeholders.

- Spring Semester (First Day) – New teams assigned.

- Spring Semester (Through February) – Designs analyzed and design drawings generated by student teams.

- Spring Semester (End of February, Early March) – Subsystem prototypes generated by student teams.

- Spring Semester (Mid April) – Alpha prototype completed and presented to stakeholders.

- Spring Semester (Early May) – Beta prototype completed, presented to client, and demonstrated.

- Summer – Student team works to finalize a design based on beta prototypes.

- Fall Semester (Following Year) – Final product given to client.

Challenges encountered

Our journey over the past five years has lead to the well-organized and coordinated course described in this paper. Many lessons over those five years have been learned with respect to the sophomore design experience. The following list highlights the lessons learned that are transferable to other institutions:

- People and place must be aligned for engagement outside the classroom. For example, when people and place are misaligned, the client is not engaging the students and visa versa. All time is spent trying to keep the project moving forward and building the relationships rather than maintaining them.

- Partnerships with local experts are necessary. One or two faculty members will not have all the expertise needed, or the availability to work one-on-one with all the students and the client. The added benefit is that students get to interact with stakeholders outside the department and/or University.

- Need to regularly bring the client to the campus. Bringing the client to where the students are lowers the hurdle for them to engage with the client as not all have access to appropriate transportation. Also, regular weekly meeting times allow students to plan ahead for client meetings.

- Client and client’s family must to be interested in the opportunity and willing to participate for the entire year. Ensure that clients do not find the project timeframe daunting and the scope unrealizable. Rather, seek out clients that find the project exciting and a great opportunity.

- Requires a lot of faculty and client time. Faculty must be willing to spend out of class time with the client, which is crucial for relationship building. Faculty must also be willing to support students during the build in the second semester by showing up to the lab in the evening. Spending time with the students in the lab ensures that we are all in this project together and further motivates them to complete a working beta prototype by the end of the semester.

- Students need to recognize themselves as a stakeholder beyond grades. Activities and discussions should be in place so students understand that their decisions as an engineer not only affect the company that they work for (the University and the Department), but that those decisions also affect the broader community and the global system (the client and the client’s family).

- Space is essential and includes: team storage space, seminar space, conceptual design space, dirty making space, and testing space. It is too much of a burden to expect the students to provide this resource, especially with large teams. By providing the necessary spaces, the students can focus their efforts on the design rather then where to house everything.

Major outcomes

Over the course of the project, we have constructed five working prototypes for five unique individuals with cerebral palsy.

Innovations, impact and successes

Each year, an individual who has not been able to independently ride a bicycle prior to working with our students is given an opportunity to receive a custom-made human-powered vehicle that can provide both independence and exercise. The impact is on the students, the faculty, and the families involved.

Olga Pierrakos

Olga Pierrakos

Eric Pappas

Eric Pappas

Tom Moran

Tom Moran

Les Welch

Les Welch

Robert Nagel

Robert Nagel

Jacquelyn Nagel

Jacquelyn Nagel

Elise Barrella

Elise Barrella

Kyle Gipson

Kyle Gipson