Goals of the project

Tessellation is a student project developed through the course, Experimental Materials Lab, in the Product Design program at the University of Oregon. The University of Oregon offers a curriculum that advances early stage scientific research into more viable products for broad applications in the market. Making at the University of Oregon encompasses both, the traditional production of a workable prototype, and also embraces unconventional forms of making. Experimental Materials Lab offers an opportunity to develop materials through an interdisciplinary collaboration between academic departments in design, science, and business. This creates an environment to synthesize and translate diverse expertise into pragmatic design products.

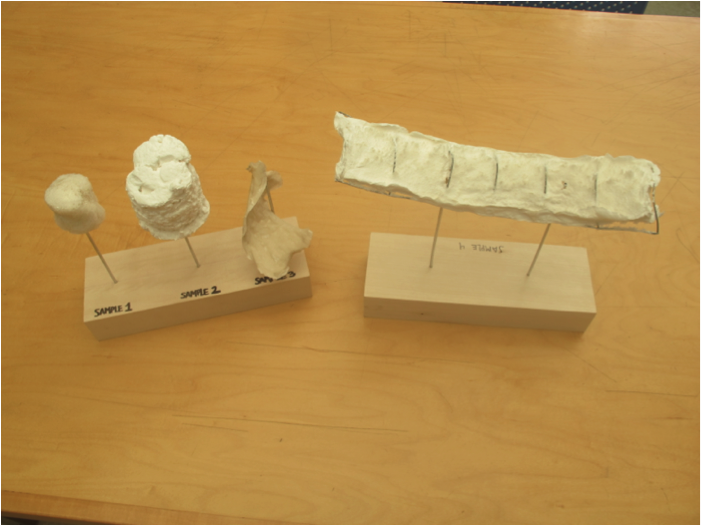

BLK LDG was an outcome of Experimental Materials Lab. It is a materials company that uses innovative processes and Nano Cellulose to create highly effective and socially responsible materials for use in buildings and objects. Its first project, Tessellation, is the first truly sustainable building insulation material. This rigid foam is created entirely from green plant matter acquired from a number of industry waste streams.

Nature of the Collaboration

This project is a collaboration between the Experimental Materials Lab in the Product Design program at the University of Oregon, BLK LDG, and the Wood Science Engineering Department at the Oregon State University. In Experimental Materials Lab, students source innovative new materials and production processes. Through rigorous design research and experimentation, students explore materials and their embedded potentials, and integrate them into tangible design products with thoughtful production methods.

In 2013, students researched the development of environmentally friendly, energy efficient building products - primarily windows and doors. Students researched the inherent problems and challenges of these products and worked to develop practical solutions. BLK LDG’s Nano Cellulose insulation material is one example of the course that was the result of this collaboration between design and science programs. The project was presented at the International Living Future Institute conference in May, and received positive feedback from business and industry.

Skills

- Research

- Ideation

- Material experimentation

- Drawing

- Computer Aided Design (CAD)

- Computer Aided Manufacturing (CAM)

- Wood working

- Vacuum forming

- Mold making

- Casting

- Prototyping

- Testing

Tools

CNC, 3D Printer, Laser Cutter, Vacuum Former were used for mold making and early stage prototyping.

Process

The insulation material that originated from the University of Oregon, Experimental Materials course was submitted to a green building design competition by Oregon Best and Living Future. From this competition, it was awarded funding for prototyping, and won 2nd place in the competition. BLK LDG was formed with the prize money, and has been working toward creating products for the market.

Milestones

Major milestones in sequential order:

- Oregon BEST Red List Design Challenge Finalist

- Initial prototypes and samples created

- 2nd place in Oregon BEST Red List Design Challenge

- Additional larger scale prototypes made

- Awarded NCIIA (VentureWell) Stage I grant

- Joined RAIN Regional Accelerator

- Large scale sheet prototype produced (Two 18” x 24” sheets)

- Validation from building contracting companies and architects

- Acceptance into Think Beyond Plastic Accelerator in Menlo Park

- Awarded VentureWell Stage II grant

Challenges encountered

Finding the necessary funding to acquire prototyping tools and market feasibility have been the biggest obstacles for BLK LDG.

Major outcomes

The project has raised ~$30,000 in funding and has received a considerable amount of publicity, press and support from local communities and industries.

Innovations, impact and successes

The building materials industry has a long-standing tradition of using highly toxic materials to achieve product efficiency and low cost. BLK LDG’s use of Nano cellulose is the first to challenge this common practice in the pursuit of a more sustainable product with a positive impact. Additionally, BLK LDG has been able to create a biopolymer that is lightweight and has the tensile strength that is twice that of steel. One explored application for this material is use in intermodal freight containers. By reducing the weight of the container, BLK LDG estimates it can reduce the use of crude oil by 35,000 barrels per cargo ship voyage.

Alexander Eckblad

Alexander Eckblad

Jonathan Hunt

Jonathan Hunt

wonheea

wonheea