Course Profile

Goals of the Course

Graduate students are given the ability to rapidly prototype their innovations to exploit the explosion of growth in Making capabilities at the University of Hawaii. Much of this effort helps benefit faculty research as devices can be developed locally and rapidly iterated upon.

Who is it designed for?

Graduate students are the target audience for this course; however, advanced undergraduate students are also highly encouraged to participate.

Learning Objectives

A student should demonstrate mastery of the (i) principles of modern rapid-prototyping of electrophysical devices, (ii) the principles of design, fabrication, testing, and iteration within the context of an application domain, (iii) be proficient in building, measuring, and evaluating prototype performance, and (iv) professionally disseminating the results.

Maker skills it develops

Students should be proficient in printed circuit board (PCB) manufacturing, laser-cutting, 3D printing, and embedded hardware design. They should understand how to use the tools (CAD and simulation packages) to design their prototypes. They should also be comfortable in an agile management (short-design cycle) framework necessary for rapid prototyping.

Prerequistes

Graduate standing or consent of the instructor.

Skills, Tools and Technologies Used

Students are given a formal introduction to rapid prototyping and Making tools including 3D printing (and other extrusion and additive processes), wet etching and laser-cutting (and other CNC-based and subtractive processes), printed-circuit board (PCB) manufacturing and related design tools, and embedded-circuit programming (e.g., Arduino).

Key Examples and Prior Work

Prior published articles on previous scientific accomplishments in the Maker movement are examined during the class. Some examples include:"A review of rapid prototyping technologies and systems." Computer-Aided Design 28.4 (1996): 307-318.

Sreetharan, Pratheev S., et al. "Monolithic fabrication of millimeter-scale machines." Journal of Micromechanics and Microengineering 22.5 (2012): 055027.

Mironov, Vladimir, et al. "Organ printing: computer-aided jet-based 3D tissue engineering." TRENDS in Biotechnology 21.4 (2003): 157-161.

Key Resources

Recent publications are provided for the course including journal articles, online tutorials and videos.

Example Assignment

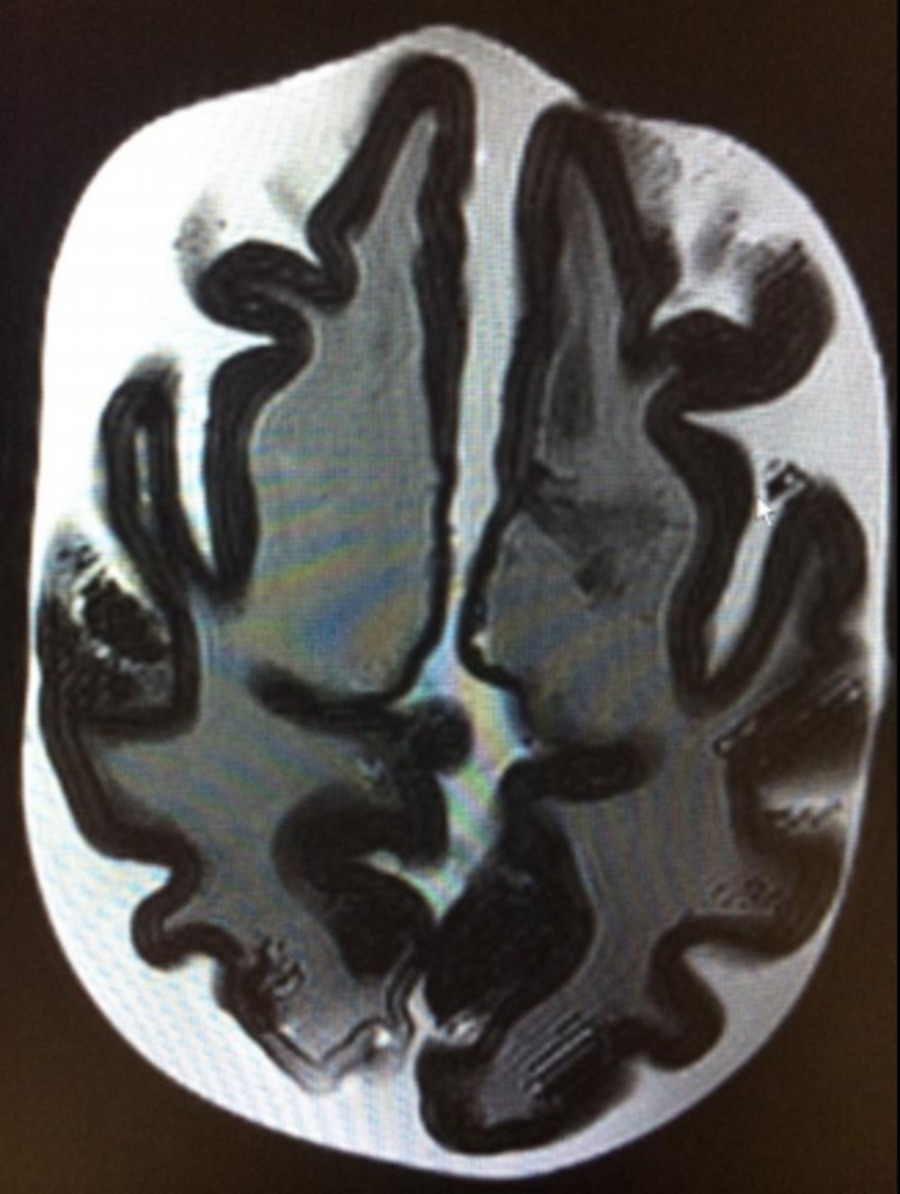

One example of an independent assignment by a student of the course was the 3D printing of an MRI phantom by Kyoko Fujimoto (supervised by Dr. Andy Stenger). MRI Phantoms have traditionally been expensive and not anthropomorphic. By creating and post-processing a 3D model of the human brain from public sources, Kyoko was able to 3D print a brain boundary layer and fill it with precisely calibrated solutions to create a low-cost MRI phantom that is also geometrically accurate. After subsequent work, she was able to publish her results in a premier MRI conference (Fujimoto, K et al. A Structurally Anthropomorphic Brain Phantom, OHBM 2015).

Lessons Learned

This course started out as a special topics course, but because of the overabundance of enthusiasm for the course, it is in the process of being approved to become a core electrophysics course (EE 626). The course has been improved to include the latest details of rapid prototyping technology and better integration with the UH FabLab for providing hands-on learning of the Making equipment.