Makerspace Profile

Overview

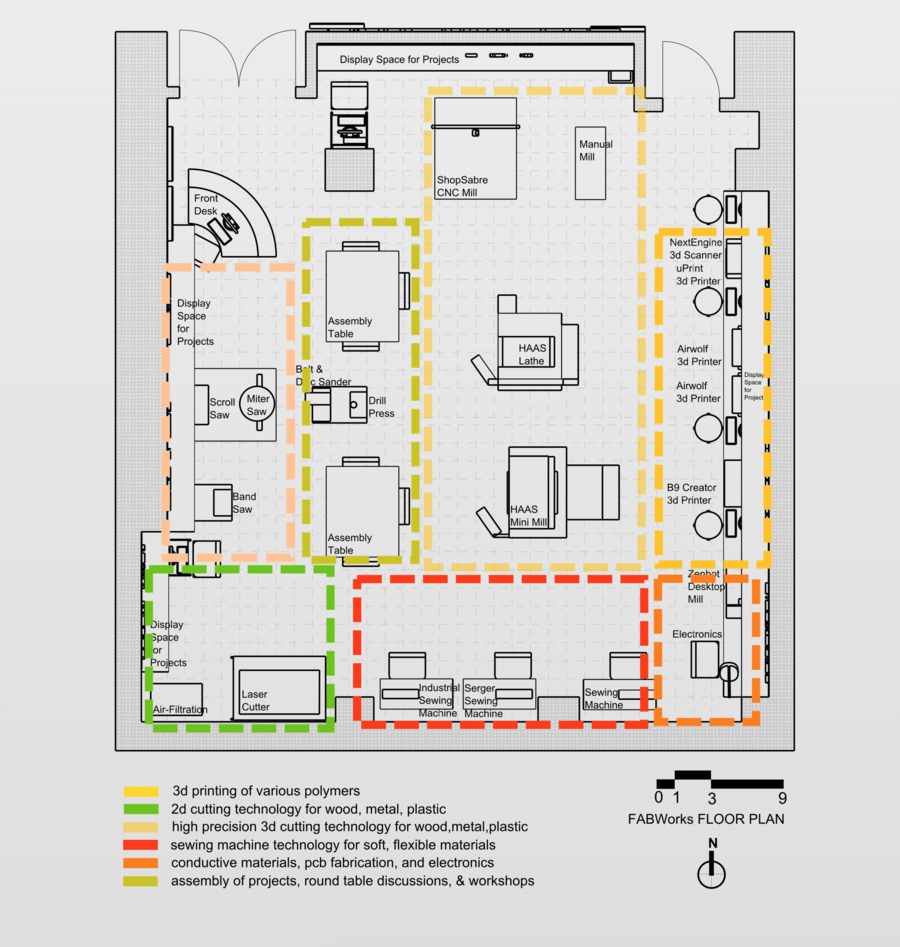

FABWorks is a MakerSpace located at University of California Irvine in the Calit2 building, Room 2302. It was built in order to expand experiential learning opportunities for students and the local community for hands on rapid prototyping and advanced manufacturing tools and processes. FABWorks is affiliated with the Henry Samueli School of Engineering and the Kay Family Foundation.

Access

The space is accessible by student, researchers and faculty at UCI. In additional, members of the local community are able to access the space to work on personal projects as well. It is available by signing up in person at the FABWorks facility, and taking a machine specific training session. Upon completion of trainings, users have access to specific machines which have an associated hourly rate.

Tools, Materials and Resources

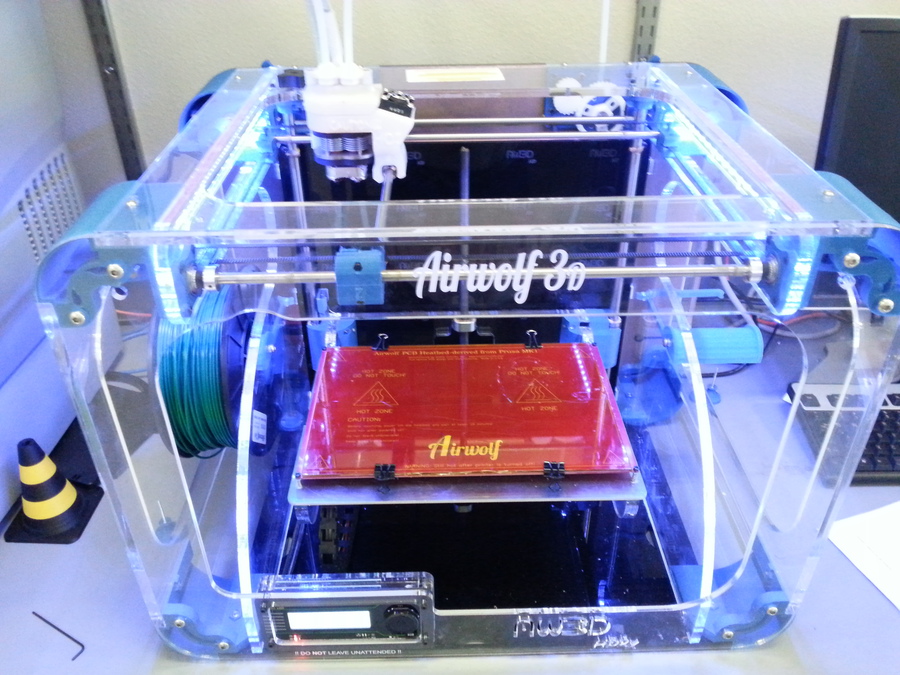

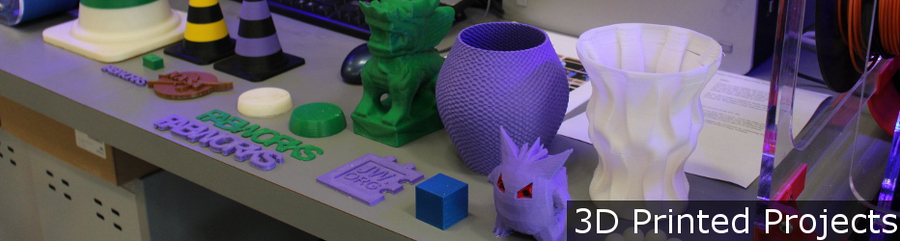

Machines available include 3d printers(AirWolf Hd, Uprint SE, B9 Creator), laser cutter(Epilog) 3d scanner(NextEngine), networked computer controlled milling machines(HAAS Lathe, Mill, ShopSabre), electronics development and diagnostics equipment, industrial sewing machines(Juki Serger and heavy duty), Vinyl Cutter(Roland) a manual mill(Smithy), and a wood shop area.

Access & Usage Costs

Access and training in the space is free. Users pay an hourly usage rate associated with each machine, and provide their own materials.

Management

FABWorks is managed by the FABWorks Director,Sarah Hovsepian. Additionally, 3 student interns are available a couple hours a week. A calendar of classes is updated weekly for training sessions held in FABWorks.

Training

FABWorks provides comprehensive and safety specific Safety and Basic Use (SBU) training for each machine in the space, ranging from 1-2 hour classes in person at designated times each week. Users have the opportunity to develop skills which include additive and subtractive manufacturing techniques, 3d modeling and design, & hands-on prototyping techniques.

Use and Activity

The space is currently mostly used for machine specific training sessions. We also have ‘open shop nights’ which offer users informational sessions and access to the shop to learn about how to fabricate and use some of the tools we offer. Additionally, we offer tours to UCI and Non-UCI affiliated users and Industry. Workshops are also held for local middle school and high school students, working in conjunction with RapidTech and FABCamp for hosting fabrication sessions in the FABWorks space.

Culture and Community

FABWorks has allowed user’s who would otherwise not have had access to our machines the opportunity to have hands on training and experience on a suite of machines. People can come in and tinker and build their own projects or inventions in a Do-It-Yourself space and/or seek help from FABWorks in order to build the project for them. It has fostered a collaborative and creative spirit, through the hosting of ‘Open Shop Nights” that allows for networking with other users from UCI and the local community, member who present current projects they’re working on in the space, and allows for open dialogue where users can ask questions, learn about new machines and processes, and make connections with others.

Challenges and Lessons Learned

Some challenges include learning how to manage the range of projects with few staff members, and streamlining signup protocols to minimize documentation. We overcame signup protocols and the documentation by creating digital forms and digital calendars for all of our member signups. User’s can also use the website to check for machine training sessions, instead of calling the facility to check on training availability etc.

Advice to other Makerspaces

It is important to capture information and document digitally so as to make information relevant to everyone available in one area. Training documentation for machines need to be simple, clear and concise, addressing the most important issues one encounters on any one of the machines. It is also important to have a designated person in charge of maintenance of the machinery, and another in charge of day to day affairs and operations of the space.