Makerspace Profile

Overview

America Makes, the National Additive Manufacturing Innovation Institute, came to Youngstown in August 2012. YSU recognized the need to create an additive manufacturing lab that would complement the America Makes Innovation Factory. CIAM was launched by the College of STEM in January 2014. It is located in Moser Hall. Equipment for the facility was supported by the university, Ohio Third Frontier, Ohio Board of Regents, and the Appalachian Regional Commission.

Access

CIAM can be used by students and faculty as part of lab courses and research projects. Access is arranged through the CIAM Lab Manager

Tools, Materials and Resources

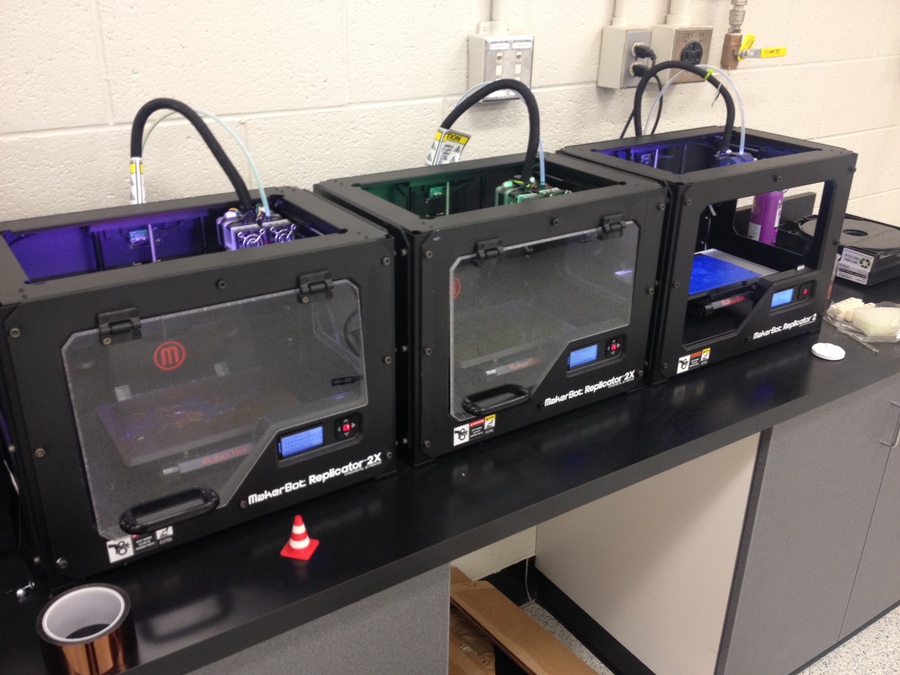

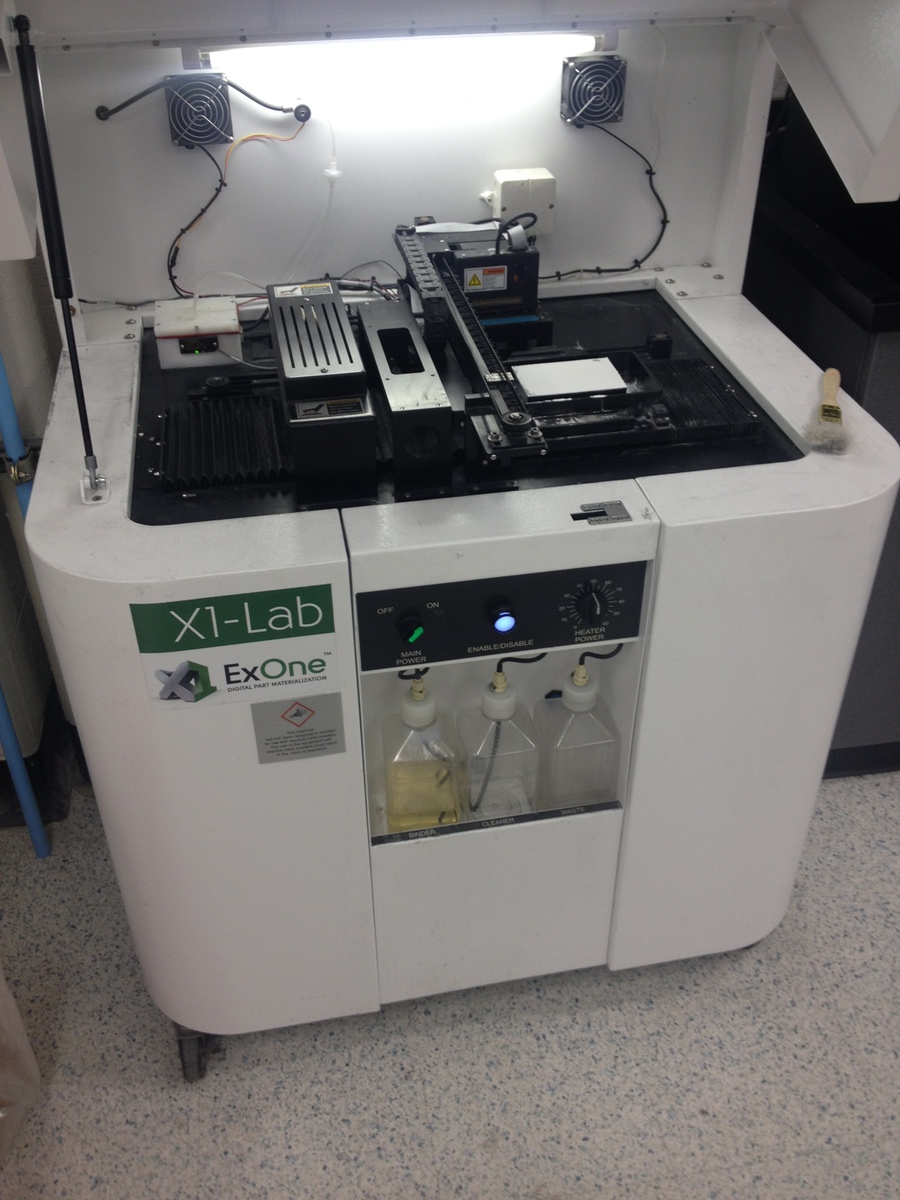

ExOne M-Flex and X1-Lab binder jetting 3D printers and associated sintering furnaces, Hybrid Manufacturing Technologies AMBIT directed energy deposition system, Stratasys Fortus 250mc material extrusion 3D printer, open source low-cost 3D metal printer, two MakerBot Replicator 2X material extrusion 3D printers, one MakerBot Replicator 2 material extrusion 3D printer, 3D Systems Capture structured light 3D scanner, and CNC machining.

Access & Usage Costs

Projects at CIAM can be funded by internal or external grants or lab fees.

Management

CIAM has a dedicated Lab Manager and two to three student lab assistants.

Training

YSU plans to offer a four year manufacturing engineering degree. CIAM is utilized by undergraduate and graduate students in several STEM departments (both engineering and sciences).

Use and Activity

The space is used for course labs, classroom tours, research projects, Crash Day, and STEM Showcase.

Culture and Community

CIAM has been a significant catalyst for transforming engineers from theoreticians to doers/makers. There has been a substantial impact that can be seen in student projects and research due to access to these capabilities.

Challenges and Lessons Learned

Key challenges sustainable funding for maintaining equipment and providing consumables, shared use arrangements outside of YSU, creating policies (access, safety, etc.), and (up until the lab manager was hired) having personnel resources to operate the laboratory.

Advice to other Makerspaces

Planning is critical. Create a plan for every aspect of the lab and secure the resources to execute the plan. Be OK with taking small steps to reach the vision of the MakerSpace.