Makerspace Profile

Overview

The Artisan and Fabrication Laboratory (AFL) is designed to be a completely student-based laboratory, which means that the lab is set up for student use while being overseen by lab employees to maintain safety. The goal of the AFL is to host student academic projects (including student organization projects), entrepreneurial projects, personal projects, and faculty research projects. The AFL is located in the basement of The Neal Armstrong Hall of Engineering. The AFL is sponsored by the College of Technology, the College of Engineering, and the Burton D. Morgan Center for Entrepreneurship.

The AFL is comprised of 5 spaces in the lower level of the Armstrong Hall of Engineering. These spaces include the following facilities:

- Artisan Lab: for working with woods, plastics, etc.

- Fabrication Lab: for working with metals and fabrication

- Unclean Room: an area with a small fume hood to perform small painting/glue tasks (aerosol paint only)

- Demonstration Studio: for developing and simulating CAD/CAM programs to be used on the machines in the AFL

- Prototyping Studio: an area that houses three Rapid Prototyping machines

Access

As normal business practice, AFL users will work with the AFL Supervisor to schedule time on machinery and/or use equipment. When necessary, scheduling will be based upon the following priorities: 1) undergraduate and graduate academic projects, including student organizations; 2) undergraduate and graduate entrepreneurial projects; 3) funded graduate student research projects; 4) undergraduate and graduate personal projects. All students from first year students to graduate and PHD students, faculty and staff have access to the AFL to do any type of project from academic projects, research projects, club projects, and entrepreneurial projects. The AFL is open 7 days a week, Monday 9am – 5pm, Tuesday thru Thursday 9am – 9pm, Friday 9am – 5pm, and Saturday and Sunday 1pm – 6pm.

Tools, Materials and Resources

The Artisan and Fabrication Laboratory (AFL) is a lab designed to provide students at Purdue with hands-on access to a state of the art manufacturing facility. Equipment available in the AFL ranges from CNC mills and lathes to wood working machinery, and includes unique capabilities such as 5-axis machining, water-jet cutting, laser cutting, and a 3-D gantry sheet router.

Artisan Lab

• (Art) Drill Press

• (Art) Vertical Band Saw

• Belt/Disc Sander

• Buffer Wheel

• Compound Miter Saw

• Cordless Drills/Power Tools

• Gantry Sheet Router Travel: (X Y Z)(96" 72" 11")

• Max RPM: 30,000

• Max HP: 15

• Horizontal Band Saw

• Iron Worker Metal Shear / Break

• Planer

• Table Saw

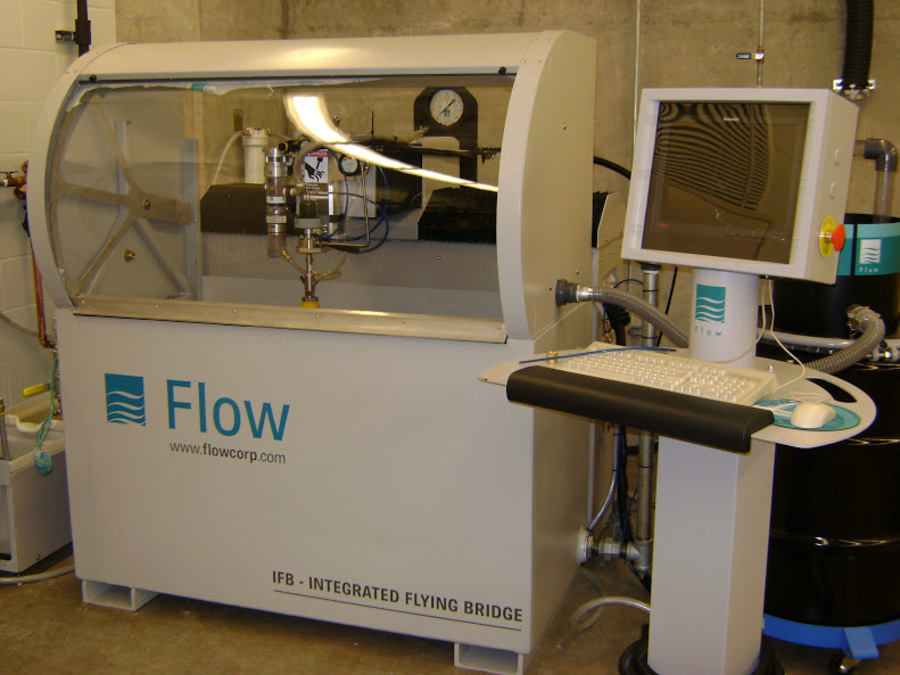

• Water Jet Table Area: (X x Y)(40" x 20")

• Cutting Area: (X x Y)(38" x 16")

Fabrication Lab

• (Fab) Drill Press

• (Fab) Vertical Band Saw

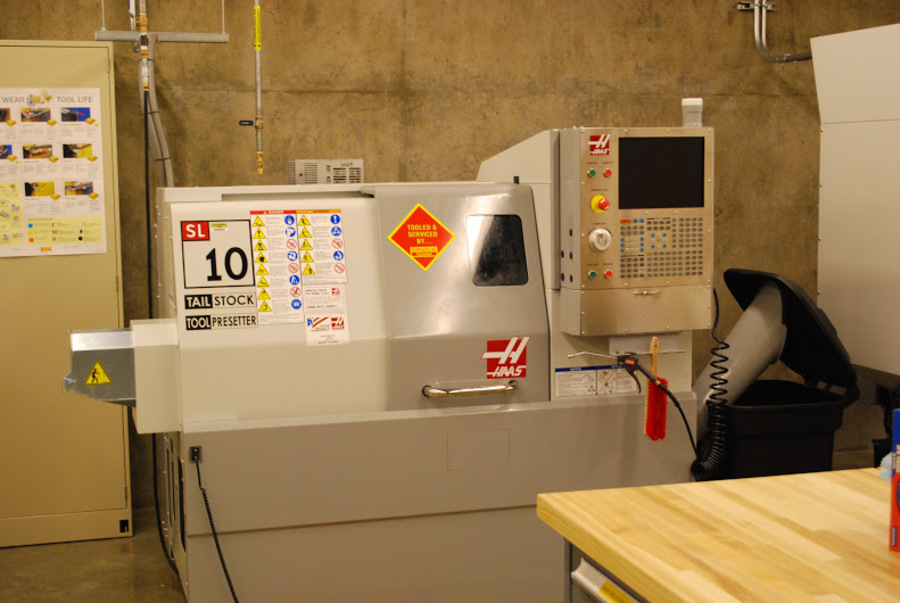

• CNC Lathe Machine Specs, Travel: (X Y) (6" 14”)

• Max RPM: 6,000

• Max HP: 7.5

• Haas Mini-Mill Travel (X,Y,Z) (16”x12”x10”) Travel: (X Y Z) (16" 12” 10”)

• Max RPM: 6,000

• Max HP: 7.5

• Haas VF2 Mill Travel: (X Y Z) (30” 16” 20”)

• Max RPM: 10,000

• Max HP: 15

• Haas VF2-SS Mill Travel: (X Y Z) (30” 16” 20”)

• Max RPM: (12000)

• Max HP: (20)

• Laser Cutter Table Area: (X x Y)(24" x 21")

• Engraving Area: (X x Y)(20" x 12")

• Pedestal Grinder

• Surface Grinder

• TIG Welder

Unclean Room

• Ventilation Hood

Access & Usage Costs

All academic, clubs, personal and entrepreneurial projects are free of charge with exception to using the Water-jet machine which is charged at consumable usage rate. Research projects are charged an hourly rate just to cover the cost of TA salary and consumables such as tooling cost. As for materials, the lab supervisor works closely with companies such as Alcoa and Nucor Steel to get certain materials donated for project use. Materials we do not have are the client’s responsibility to purchase and bring with them.

Management

Jeff Huddleston, Artisan and Fabrication Lab Manager. The staff consists of Approximately 35 Undergraduate Teaching Assistants and three Graduate Teaching Assistants and one Administrative Assistant which manages the data base with the incoming project submittals, project folders and checking in and out clients as they enter and leave the facility.

Training

The AFL is a learning facility, so we do not manufacture the project parts for the client other than for research. The AFL gives all clients the opportunity to access a high tech state of art manufacturing facility to learn the manufacturing processes from CAD/CAM, setting up the tooling, the fixturing and getting hands on with the equipment and producing/manufacturing the parts along with training from the AFL Manager, the TA’s and Grad TA’s assistance and supervision.

Use and Activity

The AFL daily sees a wide variety of projects involving a wide variety of materials. The TA’s and Director mentor and train students thru the process of CAD design to CAM to carrying out the fixture and tooling set up to operating the equipment to manufacture their parts or their projects. We do offer a class Engineering 103 to first year students and have them do project work in the AFL so that we may have a pool to choose and hire our future teaching assistants from.

Culture and Community

The AFL has given all the students, faculty, and staff a facility they can readily access to work on and produce their projects and bring their innovations to reality. The AFL has an open, very accommodating atmosphere welcoming all clients so they have a very good experience with learning the manufacturing process and achieving the end result of their innovations.

Challenges and Lessons Learned

1) The space was constructed and allocated before key personnel had the opportunity to consult with space design with respect to the type of equipment needed.

2) Getting buy-in to build a facility with state of art CNC equipment when no classes are offered to teach students how to program and operate such types of equipment

3) Funding is always critical to support growth, consumable and maintenance costs since this is a not for profit facility.

4) Turnover of students is always a recurring problem in academia. Learning how to recruit students to maintain a good top heavy knowledge base to promote an environment of peer teaching.

Advice to other Makerspaces

1) If possible get involved early in the planning of the layout and design of the space being developed or built.

2) Be part of the machine specification process.